The main task of this seminar is to thoroughly study and understand the spirit of the Fifth Plenary Session of the 18th CPC Central Committee, especially the development concept of innovation, coordination, green, openness and sharing, so as to better implement the spirit of the 18th CPC Central Committee and the Third, Fourth and Fifth Plenary Sessions of the 18th CPC Central Committee, promote the sustained and healthy development of China’s economy and society during the 13th Five-Year Plan period, and ensure the goal of building a well-off society in an all-round way as scheduled.

Since the conclusion of the Fifth Plenary Session for more than two months, all localities and departments have done a lot of work in preaching and explaining, learning and understanding, and propaganda and guidance, and achieved positive results. At the same time, we must see that the task of economic and social development in the next five years is arduous and the situation is complex and grim. To implement the spirit of the Fifth Plenary Session, we must focus on making efforts. First, we must work hard to understand it well and thoroughly. This is the main consideration for the CPC Central Committee to gather everyone together for further study and discussion.

Next, I will talk about four questions.

First, a deep understanding of the new normal of economic development

I have said many times that China’s economic development has entered a new normal. Today, I will talk about it from a historical and realistic perspective.

During the "Thirteenth Five-Year Plan" period, the remarkable feature of China’s economic development is to enter a new normal. Under the new normal, the main characteristics of China’s economic development are: the growth rate should be changed from high speed to medium speed, the development mode should be changed from scale speed to quality efficiency, the adjustment of economic structure should be changed from incremental expansion to adjustment of stock and optimization, and the driving force for development should be changed from relying mainly on resources and low-cost labor to innovation. These changes are the necessary process for China’s economy to evolve to a stage with more advanced form, more optimized division of labor and more reasonable structure. It is not easy to realize such extensive and profound changes, and it is a great new challenge for us.

"The wise change with time, and the wise make it with the world." To plan and promote China’s economic and social development during the Thirteenth Five-Year Plan period, it is necessary to take adapting to the new normal, grasping the new normal and leading the new normal as the great logic that runs through the overall situation and the whole process of development.

From the long historical process, the new state, new pattern and new stage are always forming in the course of China’s economic development, and the new normal of economic development is a stage of this long process. This is completely in line with the law of spiral upward movement of things. To fully understand and grasp the new normal, we need to examine China’s development from the perspective of time and space.

From the time point of view, China’s development has experienced several major periods from prosperity to decline and then to prosperity. Today’s new normal is the result of changes in this major period.

China was founded by agriculture in ancient times, and its farming civilization has long been at the leading level in the world. In the Han Dynasty, China’s population exceeded 60 million and cultivated more than 800 million mu. In the Tang Dynasty, Chang ‘an City had an area of over 80 square kilometers and a population of over 1 million. The palaces were magnificent, the Buddhist temples and pagodas were towering, and the eastern and western cities were very prosperous. Cen Can, a poet, wrote the poem "A million in Chang ‘an". In the Northern Song Dynasty, the national tax revenue peaked at 160 million yuan, making it the richest country in the world at that time. At that time, the populations of London, Paris, Venice and Florence were all less than 100,000, while there were nearly 50 cities with a population of more than 100,000 in China.

After the industrial revolution, we began to fall behind, while western countries developed. After the Opium War, China’s self-sufficient natural economy gradually disintegrated, and the opportunity of industrial revolution was not seized. Although some national industries developed and some foreign capital entered, such as Shanghai’s "Shili Foreign Market", Tianjin’s industry and Wuhan’s military production were famous for a while, on the whole, the country was poor, backward and war-torn, and fell behind in the trend of the times. This state lasted for more than a hundred years.

After the founding of New China, our party led the people to start large-scale industrialization. Comrade Mao Zedong pointed out that our task "is to settle down so that we can build our country’s modern industry, modern agriculture, modern science and culture and modern national defense". In the 1950s, remarkable achievements were made in national construction. Later, due to the "Left" mistakes in guiding ideology, the ten-year catastrophe like the "Cultural Revolution" occurred, and our understanding of the laws of socialist construction was not deep enough, so the large-scale industrialization construction failed to continue smoothly.

The Third Plenary Session of the Eleventh Central Committee of the Party opened a new historical period of reform and opening up. For more than 30 years, despite all kinds of difficulties, we have created the longest miracle of a country’s rapid economic growth after the end of the Second World War. China’s economic aggregate ranked eleventh in the world at the beginning of reform and opening up; In 2005, it surpassed France and ranked fifth; In 2006, it surpassed Britain and ranked fourth; In 2007, it surpassed Germany and ranked third; In 2009, it surpassed Japan and ranked second. In 2010, China’s manufacturing industry surpassed the United States, ranking first in the world. It took us decades to complete the development process that developed countries have gone through for hundreds of years and created a miracle of world development.

With the increasing economic aggregate, we have encountered a series of new situations and problems in our development. Economic development is facing the speed shift node, just like a person, he is very long between the ages of 10 and 18, and the speed of long people slows down after 18. Economic development is facing the node of structural adjustment. The overcapacity of low-end industries should be concentrated and digested, and the development of high-end industries should be accelerated. In the past, everything was profitable and how much was produced could be sold. Economic development is facing the node of power transformation, and the driving force of low-cost resources and factor input is obviously weakened, so economic growth needs more driving force innovation.

From a spatial perspective, China’s export advantage and participation in the international industrial division of labor are facing new challenges, and the new normal of economic development is the embodiment of this change.

Since the reform and opening up, an important feature of our great development is the full and effective use of the international market. Large-scale export and export-oriented development based on the advantage of low labor cost and the opportunity for labor-intensive industries in developed countries to transfer abroad have become an important driving force for China’s rapid economic growth. From 1979 to 2012, China’s export of goods maintained an average annual growth rate of about 20%, and rapidly grew into a world trading power.

The rapid development of China’s exports has also benefited from a large number of effective demands released during the golden growth period of western countries. When the international financial crisis broke out in 2008, the western countries ended the golden growth period, the economy entered a period of deep adjustment, the effective demand declined, and the import substitution effect of re-industrialization and industrial return to the mainland increased, which directly led to the slowdown of China’s export demand growth. In addition to traditional means such as anti-dumping and countervailing, western countries and other countries are increasingly demanding technical barriers to trade, labor standards and green barriers in market access, and trade frictions caused by export control measures such as levying export taxes and setting export quotas are increasing. In the past nine years, China has been the country that has been subjected to the most anti-dumping and countervailing investigations in the world. At the same time, the cost of production factors such as labor in China has risen rapidly, emerging economies such as ASEAN and other developing countries have actively participated in the international division of labor by virtue of their comparative advantages in labor costs and natural resources, and the trend of industries and orders shifting to neighboring countries in China is obvious, which has led to intensified export competition in China.

The development of global trade has entered a downturn, which is a basic trend of world economic development at present and in the future. According to statistics, in the past few decades, the growth rate of global trade has been maintained faster than the economic growth rate. In recent years, the growth rate of trade has dropped significantly, which has been lower than the growth rate of the world economy for four consecutive years. After the end of World War II, Germany and Japan experienced a period of rapid export growth and became world trade powers. From their practice, when the proportion of goods exports to the world total reaches about 10%, there will be an inflection point and the growth rate will be reduced. The proportion of China’s goods exports in the world total was less than 1% at the beginning of reform and opening up, more than 5% in 2002, more than 10% in 2010 and 12.3% in 2014. This means that the inflection point of China’s export growth rate has arrived, and it is impossible to maintain high export growth and a high proportion of exports in GDP in the future. This requires us to focus more on innovation-driven economic growth and expanding domestic demand, especially consumer demand.

In understanding the new normal, we should accurately grasp the connotation and pay attention to overcoming several tendencies. First, the new normal is not an event, so don’t judge it by good or bad. Some people ask, is the new normal a good state or a bad state? This kind of question is unscientific. The new normal is an objective state, a state that will inevitably appear when China’s economy develops to this stage, and an inherent inevitability. There is no difference between good and bad. We should seek, move and advance according to the situation. Second, the new normal is not a basket. Don’t put everything in it. The new normal is mainly manifested in the economic field. Don’t abuse the concept of the new normal and create a lot of "new normal", such as the new normal of culture, the new normal of tourism, the new normal of urban management, and even classify some bad phenomena into the new normal. Third, the new normal is not a safe haven. Don’t attribute the work that is not easy to do or difficult to do well to the new normal. It seems that there is a reason not to solve it if it is pushed to the new normal. The new normal is not to be incompetent, not to develop, not to increase GDP, but to give full play to subjective initiative and promote development more creatively. I have said this many times.

Under the new normal, despite the great downward pressure on China’s economy, China is still in an important period of strategic opportunities for development during the 13th Five-Year Plan and the next period. The fundamentals of long-term economic development have not changed, and the basic characteristics of good economic resilience, sufficient potential and large room for maneuver have not changed. The good supporting foundation and conditions for sustained economic growth have not changed, and the trend of economic restructuring and optimization has not changed. We should grasp these general trends, persist in taking economic construction as the center, adhere to the strategic thinking that development is the last word, strive for innovation in change, strive for progress in new China, and make breakthroughs in China, so as to push China’s development to a new level.

Second, about in-depth understanding of the new development concept

I have talked a lot about the development concept of innovation, coordination, green, openness and sharing at the Fifth Plenary Session of the 18th CPC Central Committee and other occasions. Today, I will not talk about it comprehensively from the perspective of grasping the work, but combine history and reality with some major issues, theoretically and macroscopically.

First, focus on implementing the innovation-driven development strategy. Putting innovation in the first place is because innovation is the first driving force to lead development. The driving force of development determines the speed, efficiency and sustainability of development. For such a large economy in China, it is difficult to achieve sustained and healthy economic development and "two doubles" if the power problem is not solved well. Of course, coordinated development, green development, open development and shared development are all conducive to enhancing the development momentum, but the core lies in innovation. Grasping innovation will seize the "bull’s nose" that affects the overall economic and social development.

Adhering to innovation and development is our conclusion from analyzing the development course of the world since modern times, especially summing up the successful practice of China’s reform and opening up. It is also our fundamental policy to cope with the changes in the development environment, enhance the development momentum, grasp the initiative of development, and better lead the new normal.

Looking back on the development of the world in modern times, we can clearly see that the innovation ability of a country and a nation fundamentally affects or even determines the future and destiny of the country and the nation.

Since the 16th century, human society has entered an unprecedented period of active innovation. For hundreds of years, human beings have made more innovations in science and technology than the sum of the past thousands of years. Especially since the 18th century, there have been several major scientific and technological revolutions in the world, such as the birth of modern physics, steam engines and machinery, electricity and transportation, relativity and quantum theory, and the development of electronics and information technology. Driven by this, the world economy has experienced many industrial revolutions, such as mechanization, electrification, automation and informationization. Every scientific, technological and industrial revolution has profoundly changed the face and pattern of world development. Some countries have seized the opportunity, and their economic and social development has entered the fast lane. Their economic strength, scientific and technological strength and military strength have been rapidly enhanced, and they have even become world powers. The first industrial revolution, which originated in Britain, made Britain take the world hegemony. The United States seized the opportunity of the second industrial revolution and overtook Britain to become the world’s number one. Since the second industrial revolution, the United States has occupied the first place in the world, because the United States is the leader and the biggest beneficiary in science and technology and industrial revolution.

The Chinese nation is brave and good at innovation. The development and glory in China’s history mentioned earlier are closely related to China’s scientific and technological inventions and innovations at that time. In ancient China, remarkable achievements were made in astronomical calendar, mathematics, agriculture, medicine, geography and many other scientific and technological fields. These inventions are closely combined with production, which provides strong support for the development of agriculture and handicrafts. British philosopher Bacon said: printing, gunpowder and compass have changed the face and state of the whole world, so that no empire, sect or figure can produce greater power and influence in the cause of mankind than these three inventions. According to some data, among the 300 most important inventions and discoveries in the world before the 16th century, China accounted for 173, far exceeding Europe at the same time. China has been in the leading position in the world for a long time in the history of development. China’s ideological culture, social system, economic development, science and technology and many other aspects have played an important role in radiating and leading the surrounding areas. Since modern times, China has gradually changed from leading to lagging behind. One of the important reasons is that we have missed the great development opportunities brought by many scientific and technological and industrial revolutions.

In today’s world, economic and social development is increasingly dependent on innovation in theory, system, science and technology, culture and other fields, and the new advantages of international competition are increasingly reflected in innovation ability. Whoever takes the lead in innovation will have the initiative to lead development. At present, a new round of scientific and technological and industrial revolution is poised for development, which is characterized by the continuous emergence of major subversive technologies, the accelerated transformation of scientific and technological achievements, and the monopoly of industrial organization forms and industrial chains. Major countries in the world have introduced new innovation strategies, increased investment, and strengthened the competition for strategic innovation resources such as talents, patents and standards.

Although China’s total economic output ranks second in the world, the problem of being big but not strong, bloated, puffy and weak is quite prominent, mainly reflected in its weak innovation ability, which is the "Achilles heel" of China’s economic giant. Leading and driving development through innovation has become an urgent requirement for China’s development. Therefore, I have repeatedly stressed that innovation means development, and innovation means the future.

After years of hard work, the overall level of science and technology in China has been significantly improved, and it is in an important period of transformation from quantitative growth to qualitative improvement, and some important fields rank among the advanced in the world. However, on the whole, the situation that China’s key core technologies are controlled by people has not fundamentally changed, the scientific and technological reserves for creating new industries and leading future development are far from enough, the industries are still at the low end of the global value chain, and there is still a big gap between China and developed countries in terms of high technology in military and security fields. We must put the development base on innovation, cultivate new impetus for development through innovation, and shape more leading development that gives full play to the first-Mover advantage.

Innovation is a complex social system engineering, involving all fields of economy and society. To persist in innovation and development, we should not only adhere to a comprehensive and systematic view, but also grasp the key points and drive the overall situation with breakthroughs in important fields and key links. It is necessary to plan ahead and deploy ahead, closely focus on the core key of economic competitiveness, the bottleneck of social development and the major challenge of national security, strengthen the basic research and common key technology research related to the overall development, comprehensively improve the ability of independent innovation, make a major breakthrough in scientific and technological innovation, and strive to realize the transformation of China’s scientific and technological level from running with others to running with others. Guided by major scientific and technological innovations, we should speed up the transformation of scientific and technological innovations into real productive forces, accelerate the construction of a new industrial system, make people have me, people have me strong, and people are strong and excellent, so as to enhance the overall quality of China’s economy and international competitiveness. It is necessary to deepen the reform of science and technology system, promote the innovation of talent development system and policy, highlight the orientation of "high precision and lack of sophisticated skills", implement a more open policy of introducing innovative talents, and gather talents from all over the world to use them.

Second, efforts should be made to enhance the overall coordination of development. "There are ups and downs, and there is this and there is another." Materialist dialectics holds that things are universally related, things and their elements influence and restrict each other, and the whole world is an interconnected whole and an interactive system. To adhere to materialist dialectics, we must grasp things from the internal relations of objective things, and understand and deal with problems. Marxist classical writers attach great importance to and are good at using materialist dialectics to understand and explore the law of contradictory movement in the development of human society. For example, Marx put forward that social reproduction can be divided into two categories: production of means of production and production of means of consumption, and the two categories must maintain a certain proportion to ensure the smooth realization of social reproduction.

In the long-term practice of leading the people to build socialism, our party has formed many ideas and strategies about coordinated development. Before and after the founding of New China, Comrade Mao Zedong put forward thinking methods and working methods such as overall consideration and "playing the piano". He said: "Playing the piano requires all ten fingers to move, and some can’t move and some can’t move. However, ten fingers are pressed at the same time, which is not a tune. To produce good music, the movements of ten fingers should be rhythmic and coordinated with each other. Party committees should pay close attention to the central work and carry out other work around the central work at the same time. We are now in charge of many aspects, and we should take care of the work of all localities, armies and departments, and we should not pay attention to only some problems and throw others away. We must point out all the problems, and we must learn this method. " On Ten Major Relationships is a model for Comrade Mao Zedong to expound the law of socialist construction from the viewpoint of universal connection. In the article "On Correctly Handling Contradictions among the People", Comrade Mao Zedong further put forward the policy of "making overall plans and making appropriate arrangements".

After the reform and opening up, Comrade Deng Xiaoping pointed out that "the task of modernization is multifaceted, and all aspects need comprehensive balance, so we can’t do it alone". In different periods of reform and opening up, Comrade Deng Xiaoping put forward a series of strategic policies of "grasping with both hands". Comrade Jiang Zemin put forward that 12 important relations with overall situation must be handled well in the process of promoting socialist modernization. Comrade Hu Jintao proposed comprehensive, coordinated and sustainable development. The 18th National Congress of the Communist Party of China put forward the five-in-one overall layout of Socialism with Chinese characteristics’s cause, and later we put forward the "four comprehensive" strategic layout, and so on. All these reflect our deepening understanding of coordinated development and the methodological significance of materialist dialectics in solving China’s development problems.

Under the new situation, coordinated development has some new characteristics. For example, coordination is both a development means and a development goal, and it is also a standard and scale for evaluating development. For another example, coordination is the unity of the two-point theory and the key theory of development. A country, a region and even an industry have both development advantages and constraints in its specific development period. In terms of development ideas, we should not only focus on solving problems and filling shortcomings, but also consider consolidating and planting the original advantages. The two aspects complement each other and complement each other in order to achieve high-level development. For another example, coordination is the unity of development balance and imbalance, and from balance to imbalance to new balance is the basic law of things development. Balance is relative and imbalance is absolute. Emphasizing coordinated development is not egalitarianism, but paying more attention to fair development opportunities and balanced resource allocation. For another example, coordination is the unification of development shortcomings and potential. China is in the stage of moving from a middle-income country to a high-income country. International experience shows that this stage is a period of concentrated outbreaks of various contradictions, and it is inevitable that development is uncoordinated and there are many shortcomings. To coordinate development, it is necessary to find out the shortcomings, make more efforts to fill the shortcomings, tap the development potential and enhance the development stamina by filling the shortcomings.

Coordinated development is the key to winning a national chess game developed during the 13 th Five-Year Plan period. We should learn to use dialectics, be good at "playing the piano", handle the relationship between local and global, current and long-term, important and non-important, and make the most favorable strategic choice in weighing advantages and disadvantages. Proceeding from the outstanding problems of unbalanced, uncoordinated and unsustainable development in China, we should make great efforts to promote the coordinated development of regions, urban and rural areas, material civilization and spiritual civilization, and promote the integrated development of economic construction and national defense construction. This is the focus of the Fifth Plenary Session in the deployment of coordinated development.

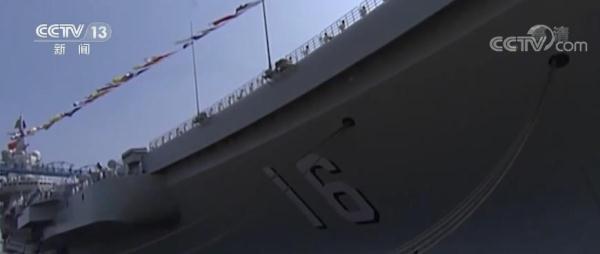

It is necessary to give full play to the comparative advantages of various regions, promote the optimization of the layout of productive forces, focus on the implementation of the three strategies of "One Belt and One Road" construction, coordinated development of Beijing, Tianjin and Hebei, and development of the Yangtze River Economic Belt, support the accelerated development of old revolutionary areas, ethnic areas, border areas and poverty-stricken areas, build a multi-center, networked and open regional development pattern connecting the East, the West and the North and the South, and continuously narrow the regional development gap. We should adhere to the policy of industry feeding agriculture, cities supporting rural areas and giving more and taking less, promote the balanced allocation of urban and rural public resources, accelerate the formation of the relationship between workers, peasants and urban areas, promote agriculture through industry, bring rural areas through cities, benefit workers and peasants, and integrate urban and rural areas, and continuously narrow the gap between urban and rural development. We must adhere to the orientation of advanced socialist culture, build consensus and pool strength with socialist core values, inspire people and boost morale with excellent cultural products, provide rich moral nourishment for the people with excellent Chinese traditional culture, and improve the level of spiritual civilization construction. It is necessary to make overall plans for economic construction and national defense construction, establish an all-factor, multi-field and high-efficiency development pattern of deep integration between the military and the people, promote national defense and army building in line with the process of building a well-off society in an all-round way, and make them develop in a coordinated, balanced and compatible way.

Third, efforts should be made to promote the harmonious coexistence between man and nature. Green development, in terms of its essence, is to solve the problem of harmonious coexistence between man and nature. Human development activities must respect, conform to and protect nature, otherwise it will be retaliated by nature, and no one can resist this law.

Engels wrote in Dialectics of Nature: The inhabitants of Mesopotamia, Greece, Asia Minor and other places destroyed the forest in order to get cultivated land, but they never dreamed that these places became barren today because they lost the forest and the water accumulation center and storage. The Italians in the Alps did not expect it when they cut down all the fir forests that were carefully protected on the northern slope of the mountain on the southern slope of the mountain. As a result, they destroyed the foundation of alpine animal husbandry in this area; What they didn’t expect was that in doing so, the mountain springs were dried up in most of the year, and at the same time, more fierce floods were poured on the plains in the rainy season.

In the last century, the "eight public hazards in the world" in western countries had a great impact on the ecological environment and public life. Among them, the photochemical smog incident in Los Angeles has caused nearly 1,000 deaths and more than 75% of the citizens suffered from pink eye. The London smog incident, which first broke out in December 1952, killed as many as 4,000 people, and nearly 8,000 people died of respiratory diseases in the next two months. Since then, there have been as many as 12 serious smog incidents in 1956, 1957 and 1962. In the Minamata disease incident in Japan, the factory directly discharged wastewater containing methylmercury into Minamata Bay, and people suffered from extremely painful mercury poisoning after eating contaminated fish and shellfish, with nearly 1,000 patients and as many as 20,000 people threatened. Rachel carson, an American writer, described these situations in detail in his book Silent Spring.

According to historical records, the Loess Plateau, Weihe River Basin and Taihang Mountains, which are now sparsely vegetated, were once forested, with beautiful scenery, suitable land for cultivation, water plants and livestock. Due to deforestation and deforestation, the ecological environment in these places has been seriously damaged. The spread of Taklimakan Desert has drowned out the Silk Road, which was in its heyday. The expansion of the desert in Hexi Corridor destroyed the ancient city of Dunhuang. The encroachment of Horqin, Mu Us Sandy Land and Wulanbuhe Desert has encroached on the rich and beautiful Mongolian grassland. Loulan ancient city declined due to reclamation and blind irrigation, which led to the diversion of Peacock River. In the paddock in northern Hebei Province, in the early years, Jyukai was vast and lush with aquatic plants. However, from the Tongzhi period, thousands of pine forests were almost gone, and hundreds of thousands of acres of barren hills and bald ridges appeared. We must earnestly learn these profound lessons.

On the issue of nature, Engels profoundly pointed out: "We should not be too intoxicated with our human victory over nature. For every such victory, nature retaliates against us. Every victory did achieve our expected results at first, but later and later it had completely different and unexpected effects, often eliminating the initial results. " Man is born of nature, and there is a symbiotic relationship between man and nature. The harm to nature will eventually hurt man himself. Only by respecting the laws of nature can we effectively prevent detours in the development and utilization of nature. This truth should be kept in mind and implemented in practice.

Since the reform and opening up, China’s economic development has made historic achievements, which is worthy of our pride and is also the envy of many countries in the world. At the same time, we must see that we have also accumulated a large number of ecological and environmental problems, which have become obvious shortcomings and outstanding problems that have been strongly reflected by the people. For example, all kinds of environmental pollution are on the rise, which has become the suffering of people’s livelihood and the pain of people’s hearts. This situation must be reversed with great efforts.

Our ancestors have long recognized the importance of the ecological environment. Confucius said, "If you fish without the outline, you will not shoot for the night." It means you don’t have to fish with a big net or shoot birds that stay overnight. Xunzi said: "when the vegetation is flourishing, the axe will not enter the forest, and it will not grow." When the giant salamander, the fish turtle and the eel are pregnant, it’s useless and poisonous, and it’s endless. " "Lu’s Spring and Autumn Annals" said: "If you fish with exhaustion, won’t you get it? And there will be no fish next year; If you burn the fields, won’t you get them? And next year there will be no animals. " These ideas about timing and moderation of nature are of great practical significance.

There is no substitute for the ecological environment. If you don’t feel it, it will be difficult to survive. As I said, the environment is people’s livelihood, the green hills are beautiful, and the blue sky is also happy, Lucid waters and lush mountains are invaluable assets; Protecting the environment means protecting productive forces, and improving the environment means developing productive forces. In the protection of ecological environment, we must establish the overall situation view, long-term view and holistic view, and we must not lose the big because of small things, pay attention to one thing and lose another, live beyond our means, and get quick success and instant benefit. We should adhere to the basic national policy of saving resources and protecting the environment, protect the ecological environment like eyes, treat it like life, promote the formation of a green development mode and lifestyle, and work together to promote the prosperity of the people, the prosperity of the country and the beauty of China. Not long ago, at the symposium on promoting the development of the Yangtze River Economic Belt held in Chongqing, I emphasized that the development of the Yangtze River Economic Belt must adhere to ecological priority and green development, and put the restoration of the Yangtze River ecological environment in an overwhelming position, and strive for great protection instead of great development. This is the consideration.

Leading cadres at all levels must have a firm belief in protecting the ecological environment, resolutely abandon development models and practices that damage or even destroy the ecological environment, and must never exchange economic growth at the expense of the ecological environment. We must firmly promote green development, promote the substantial appreciation of natural capital, make a good ecological environment a growth point of people’s lives and a force point to show China’s good image, let the people breathe fresh air, drink clean water, eat safe food, live in a livable environment, and truly feel the tangible environmental benefits brought by economic development, so as to make China’s land bluer, mountains greener, waters cleaner and the environment more beautiful, and move towards a new era of ecological civilization.

Fourth, focus on forming a new system of opening to the outside world. China’s development achievements over the past 30 years have benefited from opening to the outside world. Whether a country can be rich and strong, and whether a nation can be revitalized, the most important thing is to see whether this country and this nation can conform to the trend of the times and grasp the initiative of historical progress.

Economic globalization is the trend of the times that we have to face when planning and developing. Although the concept of "economic globalization" became popular only after the end of the Cold War, such a development trend is nothing new. As early as the 19th century, Marx and Engels wrote in German Ideology, communist party Declaration, 1857— Economic Manuscripts in 1858, Das Kapital and other works elaborated on world trade, world market, world history and other issues. The communist party Declaration pointed out: "The bourgeoisie, by opening up the world market, has made the production and consumption of all countries worldwide." These insights and expositions of Marx and Engels profoundly revealed the essence, logic and process of economic globalization, and laid the theoretical foundation for our understanding of economic globalization today.

Economic globalization has roughly gone through three stages. First, in the stage of colonial expansion and the formation of the world market, the western countries basically carved up the world by usurpation, power occupation and colonial expansion before the First World War, and all ethnic groups in the world were involved in the capitalist world system. Second, there are two parallel world markets. After the Second World War, a number of socialist countries were born, and colonial and semi-colonial countries became independent one after another. The world formed two camps of socialism and capitalism, and two parallel markets were formed economically. Third, the stage of economic globalization. With the end of the Cold War, the opposition between the two camps ceased to exist, and the two parallel markets ceased to exist. The interdependence of countries was greatly strengthened, and economic globalization developed and evolved rapidly.

Correspondingly, the relationship between China and the world has gone through three stages. First, from the closed door to the semi-colonial and semi-feudal stage, it was isolated from the world market and the tide of industrialization before the Opium War, and then it was defeated repeatedly in the Opium War and several subsequent wars of aggression by foreign powers, becoming a poor and weak country. Second, the "one-sided" and closed and semi-closed stage. After the founding of New China, we struggled to explore the road of socialist construction in a "one-sided" and relatively closed environment to the Soviet Union, and were basically isolated from the world during the Cultural Revolution. Third, the stage of all-round opening up. Since the reform and opening up, we have made full use of the opportunities brought by economic globalization, continuously expanded opening up, and achieved a historic change in China’s relations with the world.

Practice tells us that to develop and grow, we must actively conform to the trend of economic globalization, persist in opening to the outside world, and make full use of advanced scientific and technological achievements and beneficial management experience created by human society. In the early days of reform and opening up, when we were weak and inexperienced, many comrades were full of doubts. In the face of the dominant western countries, can we make use of the opportunities of opening up without being corroded or eaten? At that time, we were under great pressure to promote the negotiations on re-entry into GATT and accession to WTO. Today, it seems that we have chosen the right direction by boldly opening up and going to the world.

Twenty years ago or even fifteen years ago, the main driver of economic globalization was the United States and other western countries. Today, instead, we are considered to be the biggest standard-bearer in promoting trade and investment liberalization and facilitation in the world, actively fighting against all kinds of protectionism in western countries. This shows that as long as we actively conform to the world development trend, we can not only develop ourselves, but also lead the world development trend.

We are now engaged in open development, and the international and domestic situations we are facing are very different from those in the past. On the whole, there are more favorable factors, but the risk challenges can not be ignored, and they are all deeper risk challenges. This can be seen from four aspects. First, the balance of international power is undergoing unprecedented positive changes. The rise of emerging market countries and developing countries is changing the global political and economic map. The trend of world multipolarization and democratization of international relations is irresistible, and the global governance system dominated by western countries shows signs of change. However, the contest for the dominance of global governance and international rulemaking is fierce. The economic, scientific, political and military advantages of western developed countries have not changed, and the formation of a more just and reasonable international political and economic order still has a long way to go. Second, the world economy has gradually emerged from the shadow of the international financial crisis. Western countries have generally maintained the recovery momentum through re-industrialization, and the pattern of international industrial division of labor has undergone new changes. However, international protectionism is serious, and the formulation of international economic and trade rules has become politicized and fragmented. Many emerging market countries and developing countries have continued to slump, and the world economy has not yet found a new engine for comprehensive recovery. Third, China’s weight in the world economy and global governance has risen rapidly. China is the world’s second largest economic country, the largest exporter of goods, the second largest importer of goods, the second largest foreign direct investment country, the largest foreign exchange reserve country, and the largest tourism market. It has become a major factor affecting the changes in the world political and economic map, but the problem of China’s large but not strong economy is still outstanding.The per capita income and people’s living standards are not the same as those of developed countries, and it still needs hard work to transform China’s economic strength into international institutional power. Fourth, China’s opening to the outside world has entered a more balanced stage of introduction and going abroad. China’s opening to the outside world has changed from early introduction to a new pattern of big entry and big exit, but the corresponding laws, consulting, finance, talents, risk management and security are difficult to meet the actual needs, and the system and strength supporting high-level opening and large-scale going out are still weak.

That is to say, the overall environment of our open development today is more favorable than ever before, and the contradictions, risks and games we face are unprecedented. If we are not careful, we may fall into the trap carefully set by others. Regarding how to open up and develop in the next step, the Fifth Plenary Session of the 18th CPC Central Committee has already made arrangements, and I also made demands in my speech at the second plenary session. I hope you will continue to explore and practice, improve your consciousness and ability to grasp the overall situation at home and abroad, and improve the quality and level of opening up.

Fifth, focus on practicing the people-centered development thought. This was put forward for the first time at the Fifth Plenary Session of the 18th CPC Central Committee, which embodies the fundamental purpose of serving the people wholeheartedly and the historical materialism that the people are the fundamental force to promote development.

"Governing the country is regular, and benefiting the people is the foundation." People-centered development thought is not an abstract and abstruse concept. It can’t just stay in words and stop at ideological links, but should be reflected in all aspects of economic and social development. We must adhere to the people’s dominant position, conform to the people’s yearning for a better life, constantly realize, safeguard and develop the fundamental interests of the overwhelming majority of the people, and ensure that development is for the people, development depends on the people, and development results are shared by the people. It is necessary to deepen the drive of reform and innovation, improve the quality and efficiency of economic development, produce more and better material and spiritual products, and constantly meet the people’s growing material and cultural needs. We should fully mobilize people’s enthusiasm, initiative and creativity, and create a stage and environment for workers, entrepreneurs, innovative talents and cadres at all levels in all walks of life to play a role. We must adhere to the socialist basic economic system and distribution system, adjust the income distribution pattern, improve the redistribution adjustment mechanism with taxation, social security and transfer payment as the main means, safeguard social fairness and justice, solve the income gap problem, and make the development achievements more fair and benefit all the people.

The essence of the concept of sharing is to adhere to the people-centered development thought, which embodies the requirement of gradually realizing common prosperity. Common prosperity is a basic goal of Marxism and a basic ideal of our people since ancient times. Confucius said: "Don’t be widowed and suffer from inequality, and don’t suffer from poverty and suffer from anxiety." Mencius said: "Old people are old, young people are young, and young people are young." The Book of Rites describes the state of a "well-off" society and a "great harmony" society concretely and vividly. According to the ideas of Marx and Engels, the communist society will completely eliminate the opposition and differences between classes, between urban and rural areas, between mental work and manual work, and implement distribution according to each according to his ability, so as to truly realize social sharing and everyone’s free and all-round development.

Of course, it takes a long historical process to achieve this goal. Our country is and will be in the primary stage of socialism for a long time. We can’t do anything beyond the stage, but it doesn’t mean that we will do nothing in gradually realizing common prosperity. Instead, we should try our best to do what we can according to the existing conditions, accumulate small victories into great victories, and keep moving towards the goal of common prosperity for all people.

In the early days of the founding of New China, Comrade Mao Zedong pointed out: "Now, with such a system and such a plan, we can become richer and stronger year by year, and we can see more wealth and strength year by year. And this wealth is a common wealth, this strength is a common strength, and everyone has a share. " In the new historical period of reform and opening up, Comrade Deng Xiaoping has repeatedly emphasized common prosperity. In December 1990, when talking with several leading comrades of the Central Committee, he pointed out: "Getting rich together, we said from the beginning of the reform, will one day become a central topic. Socialism does not mean that a few people get rich and most people are poor. It is not like that. The greatest advantage of socialism is common prosperity, which is a thing that embodies the essence of socialism. " Comrade Jiang Zemin emphasized: "Achieving common prosperity is the fundamental principle and essential feature of socialism and must not be shaken." Comrade Hu Jintao also demanded that "all people share the fruits of reform and development, so that all people can make steady progress towards common prosperity". After a long and arduous struggle, the quality of life and social sharing level of our people have improved significantly, which is an amazing achievement.

The concept of shared development put forward by the Fifth Plenary Session of the 18th CPC Central Committee has four main connotations. First, sharing is shared by the whole people. This is in terms of shared coverage. Shared development is everyone’s enjoyment and proper place, not shared by a few people and shared by some people. Second, sharing is comprehensive sharing. This is in terms of shared content. Sharing development means sharing the achievements of national economic, political, cultural, social and ecological construction, and comprehensively safeguarding people’s legitimate rights and interests in all aspects. Third, sharing is co-construction and sharing. This is in terms of the realization way of sharing. Co-construction can only be shared, and the process of co-construction is also a process of sharing. It is necessary to fully carry forward democracy, gather the wisdom of the people extensively, stimulate the people’s strength to the greatest extent, and form a vivid situation in which everyone participates, everyone tries their best, and everyone has a sense of accomplishment. Fourth, sharing is gradual sharing. This is in terms of the promotion process of shared development. If you can’t eat fat in one bite, there will be a process of sharing development from low to high, from unbalanced to balanced, even if it reaches a very high level, there will be differences. We should think and design the sharing policy based on the national conditions and the level of economic and social development. We should not hesitate to spend money, nor aim too high, live beyond our means and pay lip service. These four aspects are interrelated and should be understood and grasped as a whole.

To implement the concept of shared development, there are many tasks and measures during the 13 th Five-Year Plan period, which boil down to two levels. First, fully mobilize the enthusiasm, initiative and creativity of the people, give full play to the efforts of the whole people to promote the cause of Socialism with Chinese characteristics, and constantly make the "cake" bigger. The second is to divide the growing "cakes" so that the superiority of the socialist system can be more fully reflected and the people can have more sense of gain. It is necessary to expand the middle-income class and gradually form an olive distribution pattern. In particular, it is necessary to increase assistance to people in need and resolutely win the battle against poverty in rural areas. Implementing shared development is a university question. It is necessary to do a good job from top-level design to "last mile" landing, and constantly achieve new results in practice.

Third, on the supply-side structural reform

At last year’s Central Economic Work Conference, I highlighted the supply-side structural reform, which aroused heated discussion and was recognized by the international community and domestic parties. However, some comrades told me that the supply-side reform is still not very clear, and many discussions in society are not very clear. Here, I will talk about this problem again.

First of all, I want to make it clear that the supply-side structural reform we are talking about is not the same thing as the supply school of western economics. We should not regard the supply-side structural reform as a copy of the western supply school, but also prevent some people from using their explanations to promote "neoliberalism" and take the opportunity to create negative public opinion.

The western supply school rose in the 1970s. At that time, the Keynesian demand management policy failed, and the western countries fell into the situation of economic stagflation. The supply school emphasizes that supply will automatically create demand and should start from supply to promote economic development; To increase production and supply, we must first reduce taxes to improve people’s ability and enthusiasm for saving and investing. This is the "Laffer curve" proposed by Laffer, a representative of the supply school, which is also the "tax reduction curve". In addition, the supply school also believes that tax cuts need to be matched by two conditions: one is to cut government spending to balance the budget; The second is to limit the circulation of money and stabilize prices. The supply-side school emphasizes tax reduction, overemphasizes the role of tax rate, and its thinking method is absolute, focusing only on supply and ignoring demand, focusing only on market function and ignoring the role of government.

The supply-side reform we proposed is completely a "supply-side structural reform", which I said at the Central Economic Work Conference. The word "structural" is very important, and it can be referred to as "supply-side reform" for short, but we must not forget the word "structural". Supply-side structural reform focuses on liberating and developing social productive forces, promoting structural adjustment by means of reform, reducing ineffective and low-end supply, expanding effective and high-end supply, enhancing the adaptability and flexibility of supply structure to changes in demand, and improving total factor productivity. This is not just a question of tax and tax rate, but a series of policy measures, especially those to promote scientific and technological innovation, develop the real economy, and ensure and improve people’s lives, to solve the problems existing in the supply side of China’s economy. The supply-side structural reform we are talking about emphasizes both supply and demand, emphasizes the development of social productive forces and the improvement of production relations, and gives full play to the decisive role of the market in resource allocation and the role of the government, focusing on both the present and the long-term. From the perspective of political economy, the fundamental of supply-side structural reform is to make China’s supply capacity better meet the growing, upgrading and personalized material, cultural and ecological environment needs of the broad masses of people, so as to achieve the goal of socialist production.

Supply and demand are two basic aspects of the internal relationship of market economy, and they are both contradictory and unified dialectical relations. You can’t live without me and I can’t live without you, and they are interdependent and mutually conditional. Without demand, supply cannot be realized, and new demand can give birth to new supply; Without supply, demand cannot be met, and new supply can create new demand.

Supply side and demand side are two basic means to manage and regulate macro-economy. Demand-side management focuses on solving aggregate problems and short-term regulation, mainly by regulating taxes, fiscal expenditure, money and credit to stimulate or restrain demand, and then promote economic growth. Supply-side management focuses on solving structural problems and stimulating economic growth momentum, and mainly improves the quality and efficiency of supply system by optimizing factor allocation and adjusting production structure, thus promoting economic growth.

Throughout the history of world economic development, whether the economic policy focuses on the supply side or the demand side depends on a country’s macroeconomic situation. It is one-sided to give up the demand side to talk about the supply side or to give up the supply side to talk about the demand side. The two are not an alternative relationship, but should cooperate with each other and promote in a coordinated way.

At present and in the future, China’s economic development faces problems on both sides of supply and demand, but the main aspect of contradiction is on the supply side. For example, some industries and industries in China have a serious overcapacity, while a large number of key equipment, core technologies and high-end products still rely on imports, and the huge domestic market is not in our own hands. For another example, China’s agricultural development situation is very good, but some supplies are not well adapted to the changes in demand, so it is difficult for milk to meet consumers’ requirements for quality and reputation protection. The soybean production gap is very large, while the corn production exceeds the demand growth, and the inventory of agricultural products is too large. For example, some consumer demand supported by a large amount of purchasing power in China can not be effectively supplied at home, and consumers spend a lot of money on outbound shopping and Haitao shopping. The purchased goods have extended from luxury goods such as jewelry, watches, brand-name clothing and cosmetics to ordinary daily necessities such as rice cookers, toilet seats, milk powder and bottles. According to estimates, in 2014, the outbound travel expenditure of Chinese residents exceeded RMB 1 trillion.

Facts have proved that China’s demand is not insufficient, or there is no demand, but the demand has changed, but the products supplied have not changed, and the quality and service cannot keep up. The lack of effective supply capacity has brought about a large number of "demand spillovers" and a serious outflow of consumption power. To solve these structural problems, we must promote supply-side reform.

Internationally, the current world economic structure is undergoing profound adjustment. The international financial crisis has broken the global economic cycle in which developed economies in Europe and America borrow and consume, East Asia provides high savings and cheap labor and products, and Russia, the Middle East and Latin America provide energy resources. The effective demand in the international market has shrunk sharply, and the economic growth is far below the potential output level. The level of population aging in major countries has been continuously improved, the growth rate of working population has been continuously declining, social costs and production costs have risen rapidly, traditional industries and growth drivers have been declining, and the volume and growth momentum of emerging industries have not yet accumulated. In this context, we need to make efforts from the supply side to find a correct position in the world supply market.

Domestically, economic development is facing "four drops and one liter", that is, the economic growth rate drops, the prices of industrial products drop, the profits of entity enterprises drop, the fiscal revenue drops, and the probability of economic risks rises. The main contradiction of these problems is not cyclical, but structural, and the mismatch of supply structure is serious. The marginal benefit of demand management is decreasing, and it is difficult to solve structural contradictions such as overcapacity simply by stimulating domestic demand. Therefore, we must take improving the supply structure as the main direction and realize the leap from low-level supply and demand balance to high-level supply and demand balance.

To promote the supply-side structural reform, we should start from the production side, with the focus on promoting the effective resolution of overcapacity, promoting industrial optimization and restructuring, reducing enterprise costs, developing strategic emerging industries and modern service industries, increasing the supply of public goods and services, and improving the adaptability and flexibility of the supply structure to changes in demand. In short, it is to go to capacity, to inventory, to leverage, to reduce costs, and to make up for shortcomings.

In recent years, some enterprises in China have made successful explorations in promoting supply-side structural reform. For example, in the past few years, all kinds of mobile phones in China’s market competed for each other, including foreign brands such as Motorola and Nokia, and mobile phones produced by domestic manufacturers. The competition was fierce and some enterprises went bankrupt. In this case, some enterprises in China started from the production end, insisted on independent innovation, aimed at the high-end market, and launched high-end smart phones, which met people’s requirements for more diverse functions, faster speed, clearer images and more fashionable appearance, and their market share at home and abroad continued to rise. The competition in the world mobile phone market is also very fierce. The once-famous Motorola, Nokia and Ericsson mobile phones are no longer in sight, and even become a thing of the past. After New Year’s Day, I went to Chongqing to see a company whose thin film transistor liquid crystal display is a successful case of supply-side reform. In recent years, smart terminal products such as notebook computers in Chongqing and self-owned brand automobile industry have also grown rapidly, forming the largest electronic information industry cluster in the world and the largest automobile industry cluster in China. One laptop in every three in the world is made in Chongqing. This shows that as long as we aim at the market to promote supply-side reform, the path of industrial optimization and upgrading can be completely broken out.

From the international experience, a country’s development fundamentally depends on the supply side. Time and time again, scientific and technological and industrial revolutions have brought about time and time again the improvement of productivity and created unimaginable supply capacity. In today’s era, the prominent feature of socialized mass production is that once the supply side realizes successful subversive innovation, the market will respond with magnificent transaction generation. I read a material saying that at the Cross-border Council of Emerging Technologies of the World Economic Forum in 2015, 18 scientists selected the list of the top ten emerging technologies in 2015, including fuel cell vehicles, a new generation of robots, recyclable thermosetting plastics, precision genetic engineering technology, lumber manufacturing, natural artificial intelligence, distributed manufacturing, unmanned aerial vehicles that can sense and avoid, neuromorphic technology and digital genome. When I visited Britain last year, Professor Konstantin Novoselov and Professor Andre Geim, winners of the Nobel Prize in Physics, introduced me to the research and development of graphene and its development and utilization prospects at the National Graphene Research Institute of Manchester University. Graphene is a new material with a very broad development prospect, so the British government and the European Research and Development Foundation have given strong support. These technological innovations have brought about a leap in science and technology and will also provide a strong impetus for economic development. Therefore, to promote supply-side reform, we must firmly establish the concept of innovation and development, promote the vigorous development of new technologies, new industries and new formats, and provide a steady stream of endogenous power for sustained and healthy economic development.

Fourth, about putting the new development concept into practice

The key for the new development concept to take root and become universal practice lies in the understanding and actions of leading cadres at all levels. In this regard, I emphasize four points.

First, learn deeply and use it, and let the cadres and the masses feel the truth power of the new development concept through demonstration. "The more you know, the better you will do." It takes a process for ideas to be established in people’s minds. To establish a new development concept, we need to learn constantly, deeply and persistently, and establish our consciousness and confidence in the new development concept from the depths of our souls. Leading cadres at all levels should strengthen their study of the new development concept, combine history, multidimensional comparative studies with practical studies, deeply grasp the profound summary of the development experience and lessons of the new development concept, and deeply grasp the guiding significance of the new development concept to all aspects of economic and social development, so as to truly advocate innovation, pay attention to coordination, advocate green, cultivate openness and promote sharing.

I have repeatedly stressed that leadership should have professional thinking, professional accomplishment and professional methods. Grasping the new development concept is not only a political requirement, but also an intellectual and professional requirement, because the new development concept contains a lot of new knowledge, new experience, new information and new requirements full of the flavor of the times. "The reason why poor people want to know things is just what they take for granted." If you only know some of the concepts and requirements in general, but don’t pay attention to building a knowledge system that is suitable for it, you will lack professional standards in speaking and doing things.

I have always stressed that leading cadres should become experts in economic and social management, which is targeted. With the rapid development of market, industry, science and technology, especially internet technology, leading cadres must have a high level of economic expertise. Capital investment, safe production, stock market regulation, and internet financial management and control are all high-risk and high-skilled. If you make mistakes in judgment, make careless choices, and have poor management and control, problems or even big problems will occur, which will seriously affect social stability. For some time, continuous major events in safety production, stock market and internet finance have repeatedly sounded the alarm for us. At present, economic and social management is very difficult, and there are many complicated factors. It is inevitable that some mistakes will occur, but tuition fees cannot be paid for nothing. You should learn from one’s mistakes and draw inferences from others to avoid the same mistakes. For all kinds of projects, investments and financial activities, we should make in-depth judgments and assess risks, and we should not be greedy. It is not necessary to manage the administration of decentralization and decentralization, but also to manage the management. The power released by the higher authorities must be caught by the lower levels, and there can be no vacuum zone. This is also the responsibility to defend the soil. Leading cadres at all levels should consciously strengthen their study, enhance their leadership ability, improve their management level, and constantly enhance their principles, systematicness, foresight and creativity in making decisions, doing work and grasping control.

The ancients said: "It is difficult to do things unless you know them." Unity of knowledge and action is the most important thing. Implementing the new development concept involves the change of development concept and the improvement of knowledge and ability, as well as the adjustment of interest relationship and the innovation of system and mechanism. It is necessary to put the new development concept through the whole process of leadership activities, implement it in decision-making, implementation and inspection, strive to improve the ability and level of overall implementation of the new development concept, and constantly explore new horizons of development. You can’t talk clearly, but you can do it lightly. We should enhance our overall awareness and strategic awareness, and be good at calculating big accounts, general ledger and long-term accounts, not only local accounts, departmental accounts and immediate accounts, but also not harm the overall interests for local interests and the fundamental and long-term interests for temporary interests.

Second, make good use of dialectics to carry out scientific design and construction of implementing the new development concept. The new development concept is the application of dialectics; The implementation of the new development concept cannot be separated from the guidance of dialectics. We should adhere to the systematic viewpoint and design the system according to the integrity and relevance of the new development concept, so as to promote each other and go hand in hand. We should not fight alone, pay attention to one side and neglect the other. We should adhere to the unity of the "two-point theory" and the "emphasis theory", be good at clarifying the main contradiction and the secondary contradiction, the main and secondary aspects of contradiction, distinguish priorities, firmly grasp the main aspects of the main contradiction and contradiction while taking into account the general situation, drive the overall progress with key breakthroughs, and achieve key breakthroughs in the overall progress. We should follow the laws of unity of opposites, mutual change of quality and negation of negation, be good at grasping the universality and particularity of development, gradualness and leap, progressiveness and faltering, adhere to the unity of inheritance and innovation, be pragmatic and steady, keep pace with the times, and dare to fight. We should adhere to the concrete analysis of specific problems, "ask questions in the mountains and fish in the water", take time, place and conditions as the transfer, be good at exchange and repetition, and be good at grasping the time and effect of work.

Third, innovative means, good at promoting the implementation of new development concepts through reform and the rule of law. To implement the new development concept, we must play the role of promoting reform and ensuring the rule of law. The establishment of a new concept is always accompanied by the destruction of the old concept, which is what we call unbreakable. Implementing the new development concept involves a series of changes in the way of thinking, behavior and work, and a series of adjustments in working relations, social relations and interest relations. Without reform, we can only sit and talk, and eventually we will not reach the other side. The central government’s various arrangements for comprehensively deepening reforms are connected with the implementation of the new development concept. Leading cadres at all levels must implement the main responsibility and do a good job in implementation. In the process of implementation, the principle requirements in the central reform plan can be further concretized in combination with reality; When encountering gaps in the reform plan, we can actively explore and boldly experiment; When encountering ideological resistance and work resistance, we should try our best to eliminate it, and we should not give in and compromise, and we should not relax our fighting spirit and give up halfway. It is necessary to deeply analyze the new requirements put forward by the new development concept for the construction of the rule of law, the outstanding problems encountered in implementing the new development concept in the field of the rule of law, take targeted countermeasures, and implement the new development concept by using the rule of law thinking and the rule of law.

Fourth, keep the bottom line and resolve the conflict risks in time when implementing the new development concept. Developing Socialism with Chinese characteristics is a long-term and arduous historical task, and we must be prepared for a great struggle with many new historical features. At present and in the future, we are facing many contradictory risks and challenges at home and abroad, and we must not take them lightly. Various contradictory risk challenge sources and various contradictory risk challenge points are intertwined and interactive. If we fail to take precautions and respond effectively, it will be transmitted, superimposed, evolved and upgraded, so that small contradictory risk challenges will develop into large ones, local ones into systematic ones, international ones into domestic ones, economic, social, cultural and ecological ones into political ones, and finally endanger the party’s ruling position and national security.

Promoting innovative development, coordinated development, green development, open development and shared development is based on national security and social stability. Without security and stability, nothing can be said. "The wise guard against disasters before they sprout, and the wise plan for the future." We must be proactive, prepare for a rainy day, take precautions, play the first move, fight the active battle, be prepared for any form of contradictory risk challenge, and be prepared for various struggles in economy, politics, culture, society, diplomacy and military affairs, with responsibility at all levels and everyone taking responsibility.

In 1945, Comrade Mao Zedong made a conclusion report at the Seventh National Congress of the Communist Party of China, and listed 17 difficulties in one breath when he talked about "preparing for losses" and preparing for difficulties: first, foreign countries cursed; Second, domestic abuse; Third, several large base areas were occupied by the Kuomintang; Fourth, tens of thousands of troops were wiped out by the Kuomintang; Fifth, the puppet troops welcome Chiang Kai-shek; Sixth, the outbreak of civil war; Seventh, out of Scobie, China becomes Greek; Article 8, "No recognition of Poland", that is, the status of communist party is not recognized; Article 9: Run away and scatter tens of thousands of party member; Tenth, there is pessimism and fatigue in the party; Eleventh, natural disasters are prevalent, and the bare land is thousands of miles away; Article 12, economic difficulties; Thirteenth, the enemy forces concentrated in North China; Fourteenth, the Kuomintang carried out an assassination plot to assassinate our responsible comrades; Fifteenth, the leading organs of the party have different opinions; Sixteenth, the international proletariat has not helped us for a long time; Article 17, other unexpected things. He said: "many things are unexpected, but we must think of it, especially our senior responsible cadres, who should be mentally prepared to deal with very difficult and unfavorable situations." We must thoroughly think about these. " Comrade Deng Xiaoping repeatedly stressed: "We should focus our work on the emergence of greater risks and prepare countermeasures. In this way, even if there is a big risk, the sky will not fall. "Comrade Mao Zedong, Comrade Deng Xiaoping, Comrade Jiang Zemin, and Comrade Hu Jintao have made many and profound expositions, which are very important political experience and wisdom for managing the party and the country.

Finally, I would like to emphasize another issue, that is, to mobilize the enthusiasm of cadres more extensively and effectively. This problem is extremely important, and now it seems very urgent. Party cadres are the backbone of the party’s cause. On the whole, the quality of our cadres has been continuously improved, and the structure has been obviously improved, which meets the needs of career development in general, especially a large number of outstanding young cadres are growing up. At the same time, influenced by many factors, such as growth experience, social environment, political ecology, etc., there are also various complicated situations in the current cadre team. A prominent problem is that some cadres have increased ideological confusion and low enthusiasm, and there is a certain degree of "being an official." We should attach great importance to this problem, study it carefully, make the situation clear, analyze the crux thoroughly, figure out the countermeasures and solve it in a targeted way.

According to all aspects, there are three main situations of "not acting as an official" at present: one is "unable to act" due to lack of ability, the other is "unwilling to act" due to lack of motivation, and the third is "dare not act" due to lack of responsibility. These situations have existed in the past. Why are they outstanding at present? In addition to the fact that some cadres’ own qualities can’t meet the requirements of the new situation and new tasks, there are also reasons in our work and the influence of various complicated factors in society. Judging from our work, the main reasons are that some localities and units are not perfect in implementing the implementation rules and supporting measures of the decision-making and deployment of the CPC Central Committee, the policy scale is not accurate enough, the methods and methods are somewhat simple and blunt, and the education and guidance for cadres are not in place in time. In terms of the specific operation of ideology, concept, style and economic and social development, some localities and units have not adjusted according to the new requirements since the 18th National Congress of the Communist Party of China, or have not adjusted in place, resulting in an unsuitable state. From the perspective of social factors, it is mainly negative public opinion and malicious speculation that make some cadres blur their sight and increase their confusion.